The Importance of Quality Fabrication Drawings

Though not as frequently referred to or prioritized as construction drawings, fabrication drawings have a crucial role in construction projects that should not be overlooked. Obtaining or producing quality fabrication drawings can truly make or break a project. The quality of these drawings has a significant impact on the workflow and cost of a project.

What's the Difference Between Construction and Fabrication Drawings?

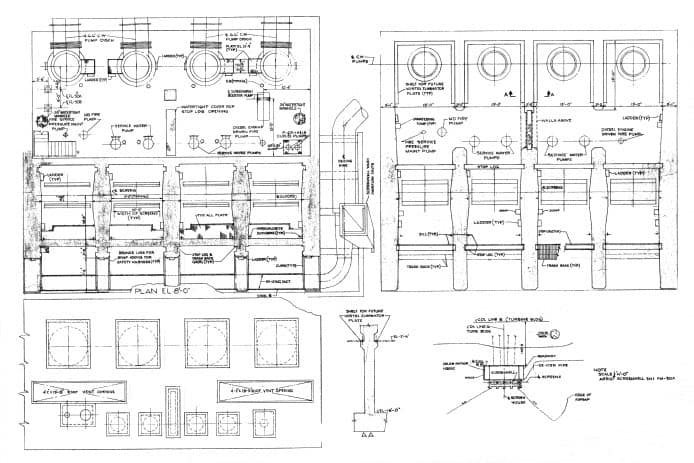

First, let’s make the distinction between construction and fabrication drawings clear. Construction drawings are a depiction of how the overall structure of the building or site is supposed to come together. Fabrication drawings illustrate how specific components and assemblies are intended to come together and be installed in a certain location within the overall construction. Think of it as a higher level, general plan and strategy vs. lower level, granular, and detailed difference. One cannot be successful without the other.

What Is the Goal of Fabrication Drawings?

Fabrication drawings accomplish three tasks:

Illustrate how individual building components must be fabricated for their intended purpose, such as a structural steel member

Define how a series of components must be assembled, such as a truss that contains several steel members and connectors

Illustrate how an assembled component (i.e. the truss above) is to be installed in the appropriate location within the overall structure

Errors in fabrication drawings may have serious consequences as regards safety, cost, and time.

What Building Components Require Fabrication Drawings?

Some of the more common building components that require fabrication drawings include structural steel assemblies (trusses, columns beams, and connections), HVAC assemblies (air handlers, sheet metal, and duct system assemblies), doors, windows, pre-cast concrete, and certainly many others depending on the project and its complexity.

What Are the Dangers of Poor Fabrication Drawings?

Fabrication drawings tend to be required for the both sensitive areas and building components that require the most attention to detail. They have an important role in the structure or performance of a building. Therefore, errors in these drawings are bound to have substantial costs concerning schedule, budget, and – most importantly – safety.

For example, suppose a steel fabricator receives a set of truss fabrication drawings that have accidentally omitted the specifications for a connecting plate that differs from the others due to a slightly higher load. Referring to these drawings, the fabricator assembles the truss using the same (but improper) connector as the other joints. The trusses (which there are likely several of) are then shipped to site and installed.

This is an example of how a major structural flaw in a complex structure could easily be overlooked and potentially not be observed until it is too late and the structure fails. In the best case, there would be indications of a structural flaw several years down the road that would indicate the need for an expensive re-fab process. In the worst case, the flaw is not discovered until structural failure leads to an accident. Then you face lawsuits due to injuries and maybe even deaths, depending on the severity of the error.

On the other hand, high-quality fabrication drawings is one of the best ways to ensure a smooth construction process and a finished project that is structurally sound and performs as planned.

How Does MLP Consulting Ensure High-Quality Fabrication Drawings?

To ensure sound, high-quality fabrication drawings, MLP follows two vital rules:

Hire experienced and creative designers, engineers, and drafters

Ensure all parties, including fabricators, understand and comply with industry standards for fabrication drawings

Experienced team members are more likely to catch any flaws or omissions in the drawings. At the same time, they’re able to produce high-quality designs more quickly. Creativity comes into play when dealing with fabrications that aren’t cookie-cutter designs. A unique design and fabrication requires the designers and drafters to illustrate the fabrication or assembly of the component in a way that leaves no room for doubt on the part of the fabricator. This may include:

Additional 3D isometric perspectives and exploded assemblies

Extra call-out drawings of a portion of the assembly

Additional carefully crafted written instructions that remove ambiguity

Based on their experience and judgment, our designers may also devise a completely different method that adds value to the drawings. Are you ready to learn how the MLP team can help your project? Our Contact page includes options to upload files and ask general questions. You can also call us at (602) 296-4090 for a no-obligation quote.